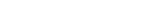

NASA has successfully flight-tested a prototype twin-fuselage towed glider that could lead to rockets being launched from pilotless aircraft at high altitudes – a technology application that could significantly reduce the cost and improve the efficiency of sending small satellites into space. The first flights of the one-third-scale twin fuselage towed glider took place Oct. 21 from NASA’s Armstrong Flight Research Center in California.

The towed glider is an element of the novel rocket-launching concept of the Towed Glider Air-Launch System, or TGALS. NASA Armstrong researchers are developing the project, which is funded as a part of the Space Technology Mission Directorate’s Game Changing Development program.

The towed glider is an element of the novel rocket-launching concept of the Towed Glider Air-Launch System, or TGALS. NASA Armstrong researchers are developing the project, which is funded as a part of the Space Technology Mission Directorate’s Game Changing Development program.

The 27-foot-wingspan towed glider was towed behind the Dryden Remotely Operated Integrated Drone, or DROID, unmanned aircraft into the blue skies above Edwards Air Force Base. Minutes later the towline was released and the twin fuselage aircraft glided to a perfect landing on the dry lakebed.

After reviewing wind conditions and checking the systems of both aircraft, mission managers decided to go for a second flight. As with the first, the glider was towed behind the DROID, leveled out in flight and the glider was released for another free flight to the dry lakebed.

“We had a really good first flight,” said John Kelly, TGALS project manager. “Both aircraft performed well.”

“It flies fantastic,” said Robert “Red” Jensen, who piloted the dual-fuselage glider. “There were no squawks.”

[image src=”http://airwingmedia.com/wp-content/uploads/2014/11/Towed-Glider-DROID.jpg” responsive=”true” lightbox=”true”]

Small unmanned aircraft technician Derek Abramson and glider pilot Red Jensen, hold back the DROID tow plane while pilot Gerald Budd runs through some last minute checks.

[hr4]

The goal is to build confidence with the aircraft and with tow operations before the final element – an experimental rocket payload – is mated with the glider and ultimately launched from the glider after its release from the DROID.

Gerald Budd, who for about three years has conceptualized and sought funding for the concept, piloted the DROID during the test flight and was pleased that the project had a successful first test flight.

“It was surreal to watch it fly after all work it took to get here,” Budd said.

If the project continues to succeed, Budd believes the ultimate goal would be to build a relatively inexpensive remotely or optionally piloted glider that will be towed aloft by a transport aircraft. Following release at about 40,000 feet, the glider would launch a booster rocket into an optimal trajectory to place its payload into low Earth orbit.

The glider was built primarily with commercial-off-the-shelf components, but some parts were manufactured at NASA Armstrong’s Fabrication Branch. Assembly was accomplished in NASA Armstrong’s Small Unmanned Aircraft Systems Research Lab, or model shop. In January, flights confirmed that towing and releasing a single-fuselage version of the aircraft by the DROID tow plane functioned as expected. The recent flights confirmed the dual-fuselage version also is airworthy.

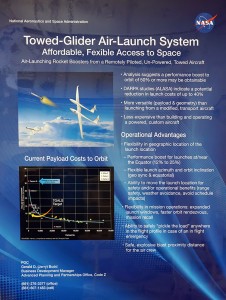

[image src=”http://airwingmedia.com/wp-content/uploads/2014/11/Towed-Rocket-Launch.jpg” responsive=”true” lightbox=”true”]

Early artist rendering shows the concept of operations of the Towed Glider Air-Launch Concept, beginning with the aero-tow of the glider carrying a rocket booster, launching the rocket, then returning to land independently of the tow aircraft. (NASA image)

[hr4]

TGALS chief engineer Ryan Dibley said using two commercial-off-the-shelf glider halves and joining them together with a center wing structure created challenges. While the center wing section was built in-house and was designed specifically for this mission, the outer wing sections were built for the standard single-fuselage glider without the additional weight.

“One of the concerns was we didn’t know what the outer wing sections were made of, how they were constructed, or what kind of loads they could take,” Dibley said. “We performed a loads test in NASA Armstrong’s Flight Loads Lab where we cleared the structure up to 2 gs to ensure that the wings could handle the loads of the glider itself and then with a partial mass payload. In the near future, we will put a wing back in the loads lab and test it to the loads required to carry the full payload.”

The system will eventually carry the scale-model Mini Sprite rocket, designed and built by Whittinghill Aerospace of Camarillo, California, under NASA’s Small Business Innovation Research program.

Initial research and development was internally funded at NASA Armstrong through the Center Innovation Fund. Potential U.S. Department of Defense and industry partners are sought for future phases.

David Voracek, NASA Armstrong chief technologist, said he is pleased to see a project that was in the Center Innovation Fund sprout wings and fly in another NASA program.

“I am happy to see that STMD is funding this for the next year under the Game Changing Development Program,” Voracek said. “We need to keep developing innovative technologies here at Armstrong that can be picked up by the NASA mission directorates or industry. I am looking forward to seeing this project continue to fly, especially when we put a rocket on the glider and get a launch off in the next year or so. The whole team came together and made the flight happen. It has been a long time in coming.”

–Jay Levine, X-Press editor

NASA Armstrong Flight Research Center

Public Affairs Specialist Peter Merlin contributed to this report.